Responsible Commitments

Responsible Commitments

Sustainability Management

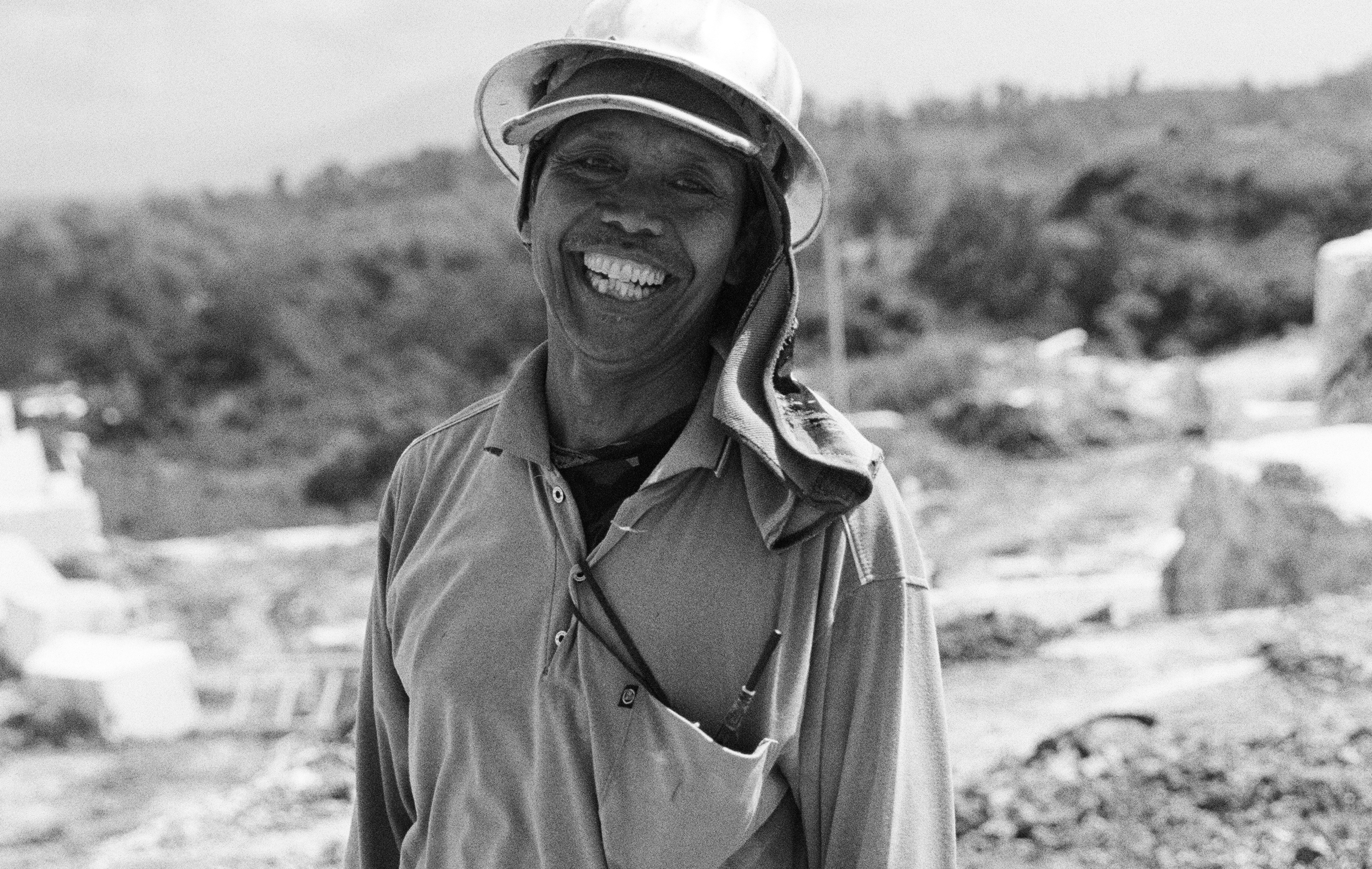

House of Slim has partnered with our community-focussed quarry and factory, who document and implement the following steps throughout their business:

- Implements new technologies as they become available and proven to reduce waste of raw materials.

- As it becomes available, efficient machines and technologies are introduced to minimize energy uses.

- Used parts of machines and consumables are recycled.

- Besides mandatory requirement to manage soil erosion, management actively plants trees surrounding the quarry hills to prevent soil erosion polluting the river system.

- Excessive soils during mining process are given free of charge to local villages for farming or building houses.

- Processes in place for recycling water

Minimising Carbon Emissions

Our factory actively replaces machines with more energy efficient ones, as they become available. In the last 4 years alone, all diesel powered air compressors have been replaced with energy efficient electric air compressors. On top of the plantation of trees on site, our factory has also planted their neighbouring community of 750 hectares of mountain area.

Water Conservation

On site, there is a rain water catchment pond to enable water conversation and recycle the water back in to the factory.

Energy Conservation

Due to the nature of our production process, we take advantage of natural daylight and open studios. The factory was designed to see enough sunlight through the production studios, where no electric lightings are required during daytime hours.

Waste Management

Excess waste from the stones are re-purposed in a multitude of ways. Firstly, excess can be turned into paste which is donated to the local community to help patch or build their houses and community places of worship. Excess stones are also donated to the local villagers to craft into smaller handicrafts to on-sell to make a living for themselves and their families. A local villager recently paid for his sons University Tuition from on-selling excess stones which were donated, which 100% of the sale was kept by the local community member. We are proud to support our partner factory who keeps community-spirit at the forefront of their business model.

Responsible Designs

In a time where mass consumption is overwhelmingly prominent, we wanted to offer a different approach for the home – investing in pieces that would last the years. All House of Slim pieces are crafted in their most natural form; from raw, earth based elements found locally here in Indonesia. Chapter I focusses on the elements of Onyx and Marble. House of Slim promotes intentional purchasing, which is why our buy in to each order is small to reduce over stocking and landfill. Any excess waste produced during the manufacturing process is strictly re-purposes. This excess is donated free of charge to the local villagers, which can then be converted to handicraft pieces or grinded for calcium production.

Local Purchasing

We set out to create a line which worked in with artisans and localised natural elements in our home of Indonesia. Our Chapter I collection focusses on elements sourced and crafted from Central Indonesia by local villagers in their direct community.

Staff Engagement

The Waste Management initiatives are developed and maintained by local staff members. Being from the local villages, they have a greater understanding and creativity on how any waste can be utilised by their community.

Local and Fair Employment

Most employees from our partner factory are paid well above award wage. Mining and engineering managers are provided with company cars, while our partner factory provides a bus for daily transport to and from the vicinity for all staff members. When working overtime, all staff are provided with meals and their wages are adjusted accordingly.